Inks

Ink detection media is often considered to have a greater level of mobility than dry powders.

Inks are a suspension of iron oxide particles in a suitable carrier fluid. There are two distinct

divisions when dealing with MT inks, these being fluorescent inks and non-fluorescent inks.

Non-fluorescent inks are usually black and referred to as black inks or powders.

Fluorescent inks are more sensitive and therefore able to locate smaller, finer indications. But they are more complex to use due to the requirement of UV-A light for inspection.

If water is used as a carrier fluid for the iron oxide particles, it should contain additives to prevent corrosion of the surface or particles, reduce surface tension and improve the wetting action i.e. surficants (wetting agents). Paraffin/ Kerosene based products are often selected primarily due to their good wetting ability. Other advantages include they are odourless, have a relative tolerance to oil or grease and are not corrosive.

BS EN ISO 9934-2 with regards ink viscosity states: The dynamic viscosity shall not be higher than 5 mPa-s at 20°C ± 2°C

Millipascal seconds (mPa-s) can be converted directly to Centipoise (CPS) and Centistokes (CSt) as it is a 1:1 conversion.

A drawback is flammability, particularly in situations such as confined or enclosed spaces, or when using techniques such as prods which can arc.

Inks can be applied both before and during magnetisation. However, the application of ink must stop whilst still applying the magnetic field to ensure indications from fine shallow discontinuities are not washed out.

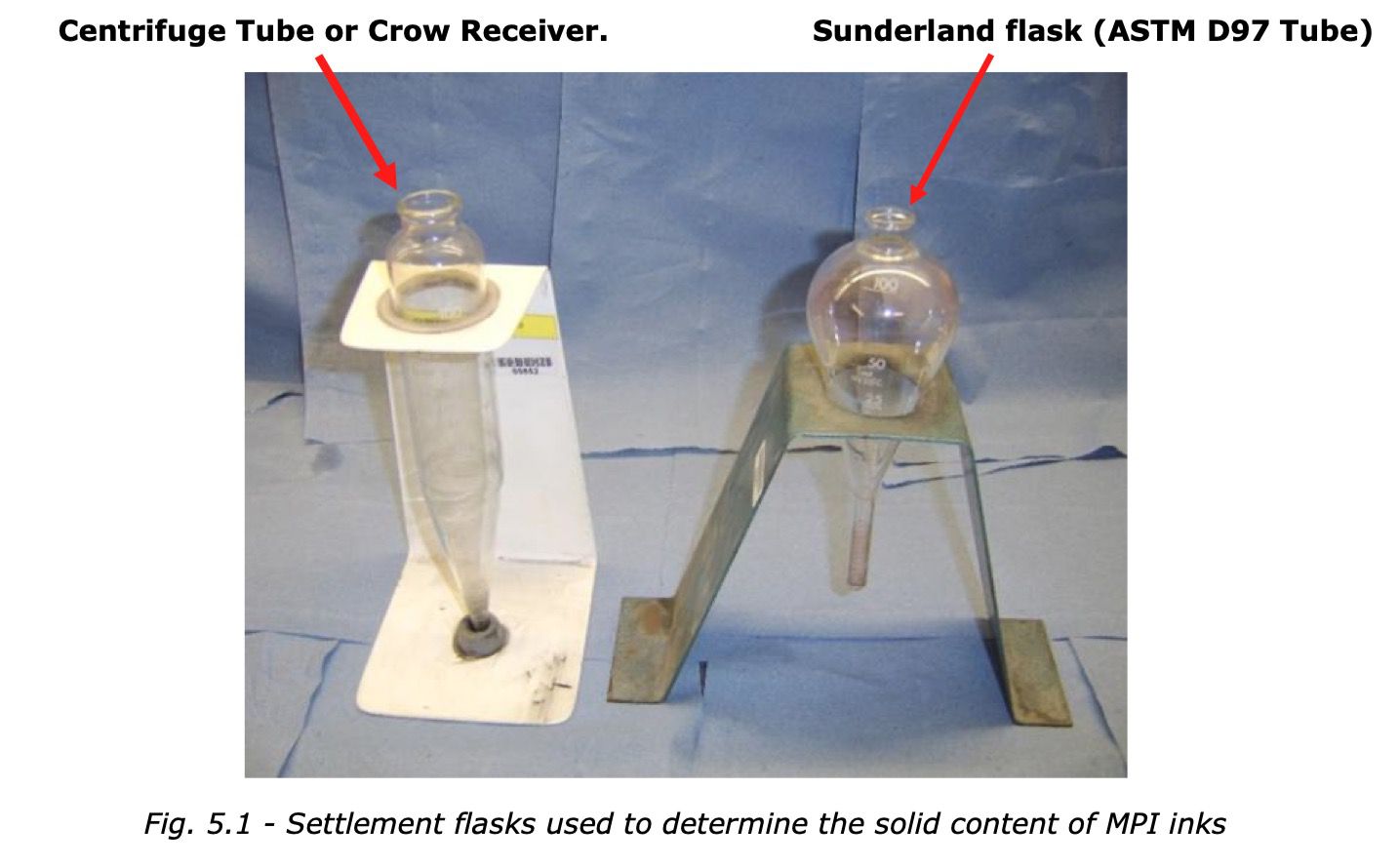

A typical method of test for assessing the solid content of magnetic inks using settlement flasks is:

- Maximum volume of magnetic ink for test should not exceed 5 litres.

- Agitate container for not less than 5 minutes to ensure particles are well dispersed.

- Pour sample of ink into 100 ml settlement flask (centrifuge type or Sutherland flask). Note: demagnetise if re-used consumables.

- Allow to settle for 60 minutes (30 minutes for water based carrier fluids).

- Read off the solid content to nearest 0.1 ml.

The solid content range is very important as too high a concentration will cause excessive background and too low a concentration will cause weak indications to be missed.

Note: Inks may be supplied as:

- Ready to use (bulk/ aerosol).

- Concentrates

- Pastes – these are less common due to difficulty in breaking down into a suspension without lumps.

Media may be applied by:

- Puffer bottle.

- Immersion

- Flowing

- Spraying

ASTM E1444 requires agitation of the particle suspension for a minimum of 30 minutes, take a 100 ml sample then demagnetise the sample, and allow to stand for 30 minutes for water based carriers or 60 minutes for petroleum distillate. Once settled, the sample can then be checked for contamination under UV and white light for fluorescent ink, or white light for black ink. If the volume of bands or striations of solid content of a different colour exceed 30% of the volume of magnetic particles or the particles appear to be loose agglomerates rather than a solid layer, the ink must be replaced.

BS EN ISO 9934-2 no longer specifies a solid content range and states the supplier will give this information in g/l. To check the overall performance there are two reference blocks referred to in Appendix B of this standard.

The carrier fluid shall make the volume up to 100%.

Typical ink concentrations used:

- Fluorescent 0.1 – 0.3%

- Non fluorescent 1.25 – 3.5%

The fluorescent coefficient of the particles is expressed in cd/W.

An additional test for fluorescent inks after settling is to check the suspension fluid (supernatant liquid) with UV-A light, if a yellow-green fluorescence is observed, all the ink should be discarded and replaced with a fresh solution. This is a comparative test to a sample of unused ink from the sample batch, since even unused ink will have a small amount of pigment detached from the ink particles.

In general, it is stated for all inks that:

- They shall form a uniform suspension when agitated.

- They shall not contain any other ingredients that are likely to cause injury to the operator either during or after use.

- The inks shall not corrode or otherwise adversely affect the surfaces of the workpieces.

- BS EN 9934-2 quotes a maximum sulphur and halogen content of 200 ppm ± 10 for designated low sulphur and halogen consumables.

- They may contain small quantities of other ingredients at the manufacturers’ discretion providing the solid content remains within the specified proportions.